Alloy Steel vs Carbon Steel: Properties, Applications, and More

- Daivik Gupta

- Feb 12, 2025

- 3 min read

Alloy steel is a specialized form of steel that is mixed with different elements to improve its mechanical properties and overall performance. In contrast to carbon steel, which mainly depends on carbon for its strength, alloy steel includes a range of additional elements like chromium, nickel, molybdenum, and vanadium to attain desired characteristics. This article explores the unique features of alloy steel, compares it to carbon steel, discusses its various grades and compositions, and outlines the manufacturing processes used in producing alloy steel.

What is Alloy Steel?

Alloy steel refers to steel that incorporates a notable quantity of alloying elements alongside carbon. These additional elements enhance particular characteristics like strength, hardness, toughness, wear resistance, and corrosion resistance. By including these components, alloy steel can be customized for a wide range of uses, making it an adaptable material across various sectors, including automotive and construction.

Alloy Steel vs. Carbon Steel

The primary difference between alloy steel and carbon steel lies in their composition and the resulting properties:

Composition:

Carbon Steel: Contains primarily iron and carbon, with carbon content typically ranging from 0.05% to 2.0%. It may also contain small amounts of manganese, silicon, and copper.

Alloy Steel: Contains iron, carbon, and additional alloying elements. The specific elements and their percentages can vary widely, leading to a broad range of properties.

Properties:

Carbon Steel: Generally has good tensile strength and ductility but may lack the toughness and corrosion resistance found in alloy steels.

Alloy Steel: Offers enhanced mechanical properties, including improved strength, hardness, and resistance to wear and corrosion. This makes alloy steel suitable for demanding applications.

Applications:

Carbon Steel: Commonly used in construction, automotive components, and general manufacturing.

Alloy Steel: Used in specialized applications such as aerospace, oil and gas, power generation, and high-stress environments.

Alloy Steel Grades

Alloy steel is categorized into various grades based on its composition and properties. Some common alloy steel grades include:

AISI 4130: A low-alloy steel containing chromium and molybdenum, known for its strength and weldability. It is often used in the aerospace and automotive industries.

AISI 4140: A medium-carbon alloy steel with chromium and molybdenum, offering high strength and toughness. It is commonly used in manufacturing gears, axles, and crankshafts.

AISI 4340: A high-strength alloy steel containing nickel, chromium, and molybdenum. It is known for its toughness and is often used in heavy-duty applications such as aircraft landing gear and high-stress components.

AISI 8620: A low-alloy steel that is carburized to enhance surface hardness. It is used in applications requiring high wear resistance, such as gears and shafts.

Alloy Steel Composition

The composition of alloy steel varies depending on the desired properties and applications. Common alloying elements include:

Chromium (Cr): Increases hardness, strength, and corrosion resistance.

Nickel (Ni): Enhances toughness and impact resistance.

Molybdenum (Mo): Improves strength at high temperatures and enhances hardenability.

Vanadium (V): Increases strength and wear resistance.

Silicon (Si): Improves strength and deoxidizes the steel during production.

The specific percentages of these elements can significantly influence the final properties of the alloy steel.

Alloy Steel Material

Alloy steel comes in a range of forms, such as bars, plates, sheets, and tubes, with the selection based on the specific application requirements. To obtain the desired shape and characteristics, this material is typically processed using techniques like forging, casting, and machining. Additionally, heat treatment methods, including quenching and tempering, are frequently utilized to improve the mechanical properties of alloy steel.

Alloy Steel Plant

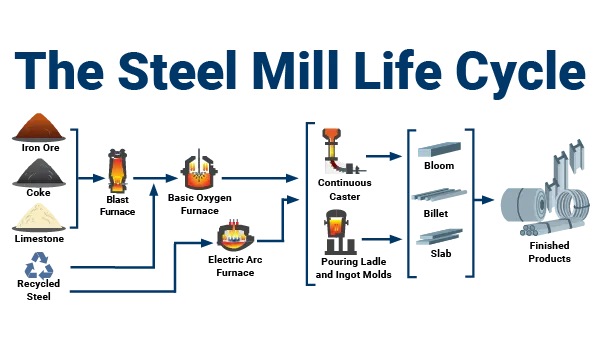

Alloy steel is usually produced in dedicated facilities that feature cutting-edge technology and processes. These specialized plants employ electric arc furnaces (EAF) or basic oxygen furnaces (BOF) to melt down scrap steel along with alloying materials. Once melted, the steel is cast into different forms and undergoes heat treatment to attain the required characteristics.

Ensuring quality is paramount in the production of alloy steel, with stringent testing and inspection protocols established to guarantee that the end product adheres to industry standards and specifications.

Conclusion

Alloy steel plays a crucial role in contemporary manufacturing and engineering, providing an exceptional blend of strength, durability, and resistance to wear and corrosion. Its adaptability enables customization for numerous applications, establishing it as a key element across multiple industries. Grasping the distinctions between alloy steel and carbon steel, along with the different types available, is essential for leveraging its full potential.

RN Gupta and Bros. is a premier steel trading firm located in Mandi Gobindgarh, renowned for our extensive range of high-quality alloy steel products. We cater to diverse industries and are the trusted choice for manufacturers across India. Whether you need steel for construction, manufacturing, or specialized projects, we have the right solutions for you.

Our commitment to quality and customer satisfaction sets us apart in the industry. Contact us today to receive a competitive quote tailored to your specific needs. Let us help you bring your projects to life with the best alloy steel available!

.png)

Comments